| Model: | HDG Internal Hex Head |

|---|---|

| Min. Order: | 10000 Piece/Pieces |

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean, Air, Land |

| Production Capacity: | 1 container each month | Packing: | Packed in box to... |

|---|---|---|---|

| Delivery Date: | as discussed | Type: | Wall Anchor |

| Material: | Carbon Steel 4.8-8.8 grade | Brand Name: | OEM |

| Diameter: | 8 mm-5/16"~~30 mm-1-/4" | Length: | 110 mm-4-1/2"~~ 380 mm-14-1/8" |

| Capacity: | Mpa Tensile loading | Function: | Without expansion fixing |

| Working mechanism: | Use chemical adhesive system to cure the stud and structure substrate | Base materials: | In the concrete,masonry,brickwork,solid wall or stone substrate |

| The end design: | Cut single / double 45 degree or flat end | The head design: | External hex head, Internal hex head and Flat head |

| Application: | Used to fix the objects or connect and reinforce structure foundation | Installation: | Pre-drill a hole in substrate and insert chemical adhesive system to cure and to install by setting tool |

| Producing engineering: | Punching machine-Cutting Lathe-Thread rolling machine | Surface treatment: | Hot dipped galvanized, Zinc plating and Dacromet spray plating |

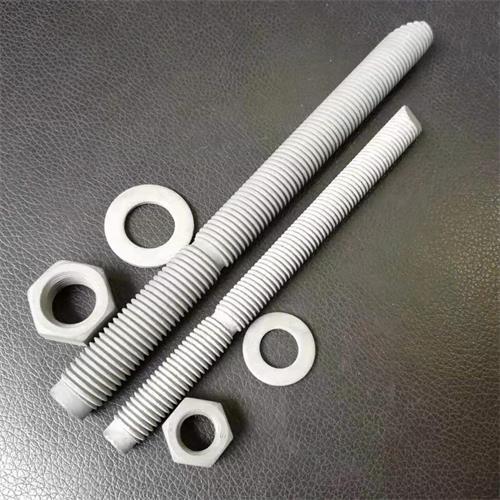

Concrete chemical studs is a chisel cutting end chemical anchor fastener, used together with injection resin or chemical glass capsule to become chemical anchor system in the concrete, solid brick wall or stone places. For installing, threaded stud is chemically bonded to the base material.The chemical bolt fixing method imposes no expansion stress on the base material, and is ideal for shock or vibratory loading and for softer or low density building materials where expansion stresses would normally result in failure.

Chemical studs is made by the carbon steel materials 4.8-8.8 grade by hot dipped galvanized,having better rust proof and anti-corrosion performance than common zinc plating,suitable for wet or underwater installation pre-assembled hex nut and washer, providing the special setting tools.

[Product features]:

■ Hot Dipped Galvanized(HDG) have better rust proof and anti-corrosion performance than zinc plating.

■ Made of carbon steel materials having 4.8-8.8 grade to realize various use purpose.

■ No expansion function.

■ High loading performance and suitable for static and dynamic loading place.

■ Design external hex head, internal hex head and flat head types to use special setting tool for installing.

■ The sharp tail design make it insert chemical glass capsule and installing hole easier and quicker.

■ Allow to use in the small space or edge of construction structure foundation.

■ Use chemical adhesive system for bonding between anchor stud and base materials in the hole to realize the fixing function, also called adhesive anchor bolts.

■ Mainly adopted chemical glass capsule or injection resin to achieve chemical bonding.

■ Allow usage in wet or underwater installing hole.

■ Also used in reinforcement concrete construction structure for connecting or reinforcing.

[Chemical Glass Capsule Compositions]: Resin + Glass + Hardener + Quartz

[Materials & Surface treatment]:

☞ Carbon steel & HDG / ZYP / ZP / Dacromet Spraying.

[Base Materials]: ☑ Concrete ☑ Masonry ☑ Brickwork ☑ Solid brick wall ☑ Stone

[Applications]:

☒ Chemical fixing for steel structure,curtain walling,cladding,precast concrete components.

☒ Tie back for temporary structures or permanent fixing.

☒ Telecom tower, Racking.

☒ Installing sign, handrails,balustrades and gates.

☒ Installation of starter rods for structural extension and rectification works.

☒ Goods shelves installing .

☒ Reconstruction and reinforcement of old and dangerous buildings works.

☒ Reinforcement concrete construction structure for connecting or reinforcing engineering.

☒ Decorative panel fixing or architectural finishes.

☒ High rise construction steel structure installing project.

☒ Power plants,tunnel construction engineering.

☒ Roads,bridges,railroad construction works.

☒ Cranes,lifts and escalators installation.

[Hardening-setting time]:

| Dry hole: | Installing | Wet hole: | Installing | Underwater hole: | Installing |

| Substrate temp. | Curing Time | Substrate temp. | Curing Time | Substrate temp. | Curing Time |

| ≥ 20℃ | 15 Min. | ≥ 20℃ | 30 Min. | ≥ 20℃ | 1.5 Hrs. |

| 10 ~ 20℃ | 25 Min. | 10 ~ 20℃ | 50 Min. | 10 ~ 20℃ | 2.5 Hrs. |

| 0 ~ 10℃ | 1.5 Hrs. | 0 ~ 10℃ | 2.5 Hrs. | 0 ~ 10℃ | 5.5 Hrs. |

| -5 ~ 0℃ | 5.5 Hrs. |

[Installation Procedures]:

❶ Drill hole in base material to ensure the proper hole diameter and depth.

❷ Use brush to remove the dirt and dust in the hole.

❸ Check the viscosity of the resin inside of glass capsule and insert a chemical glass capsule into a clean hole.

❹ Unscrew hex nut & washer to rotate threaded stud with setting tool and power tool to drive it into glass capsule till reaching the bottom of the hole.

❺ Observe the specified curing time until being solidified completely.

❻ Tighten hex nut and washer for fixing or reinforcing.

[Product size description]: (mm/inch)

| Item Code | Stud Size | Max.Thickness Fastened | Hole Dia. | Hole Depth |

| CHEMA-08 | M8 X 110 | 16 mm | 10 mm | 80 mm |

| CHEMA-10 | M10 X 130 | 22 mm | 12 mm | 90 mm |

| CHEMA-12 | M12 X 160 | 30 mm | 14 mm | 110 mm |

| CHEMA-16 | M16 X 190 | 38 mm | 18 mm | 125 mm |

| CHEMA-20 | M20 X 260 | 70 mm | 25 mm | 170 mm |

| CHEMA-24 | M24 X 300 | 65 mm | 28 mm | 210 mm |

| CHEMA-30 | M30 X 380 | 70 mm | 35 mm | 280 mm |

| CHEMAI-516 | 5/16 X 4-1/2 | 3/4 | 3/8 | 3-3/8 |

| CHEMAI-38 | 3/8 X 5 | 1 | 7/16 | 3-5/8 |

| CHEMAI-12 | 1/2 X 6-1/4 | 1-1/4 | 9/16 | 3-9/16 |

| CHEMAI-58 | 5/8 X 7-1/2 | 1-3/4 | 3/4 | 6 |

| CHEMAI-34 | 3/4 X 10-1/4 | 2-3/4 | 7/8 | 7-1/2 |

| CHEMAI-78 | 7/8 X 11-3/4 | 3-3/4 | 1 | 8-1/2 |

| CHEMAI-1 | 1 X 11-3/4 | 2-1/2 | 1-1/8 | 8-1/2 |

| CHEMAI-114 | 1-1/4 X 14-1/8 | 2 | 1-7/16 | 11-1/2 |

**The special styles and sizes could be customized.

Category: Chemical Anchors

Related Category: Ceiling Anchors Cut Anchors Hit Anchors Metal Frame Anchors TAM Shield Anchors